The way i do this is to put a small piece of wood that is about 3 8 thick on top of the material i an using and have the laser focus on the wood.

Boss laser cutter settings for different materials.

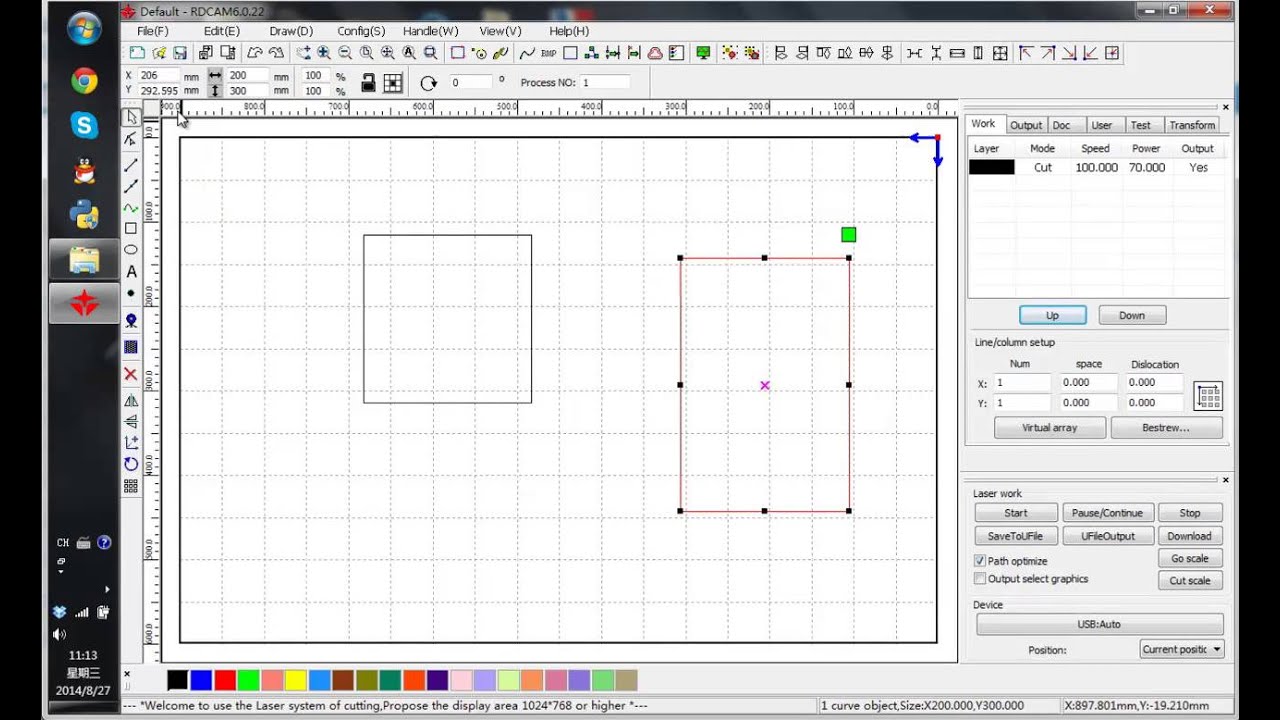

Different colors layers can be used to designate different operations on same project.

The co2 laser wavelength is not efficient at metal cutting which is why we offer a line of fiber laser cutting and marking machines.

There are a whole host of materials that a co2 laser cutter can cut etch or mark but some due to the material surface reflection just won t work aluminum is an example.

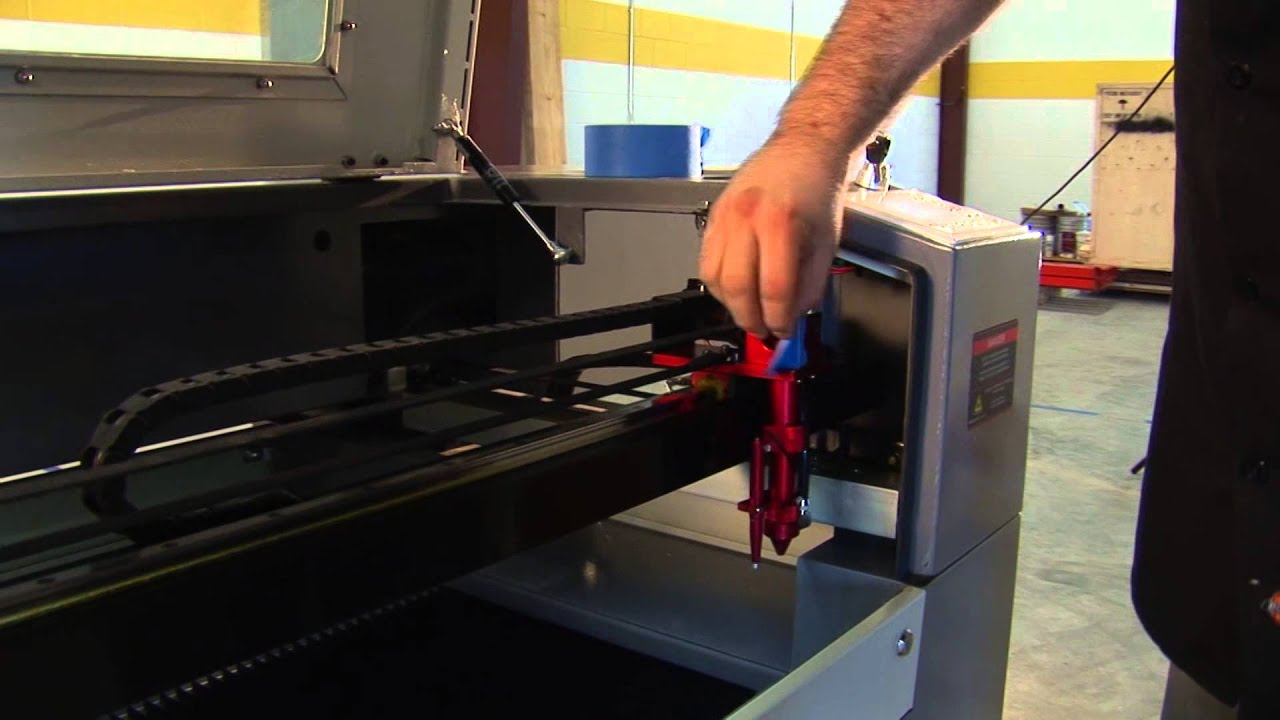

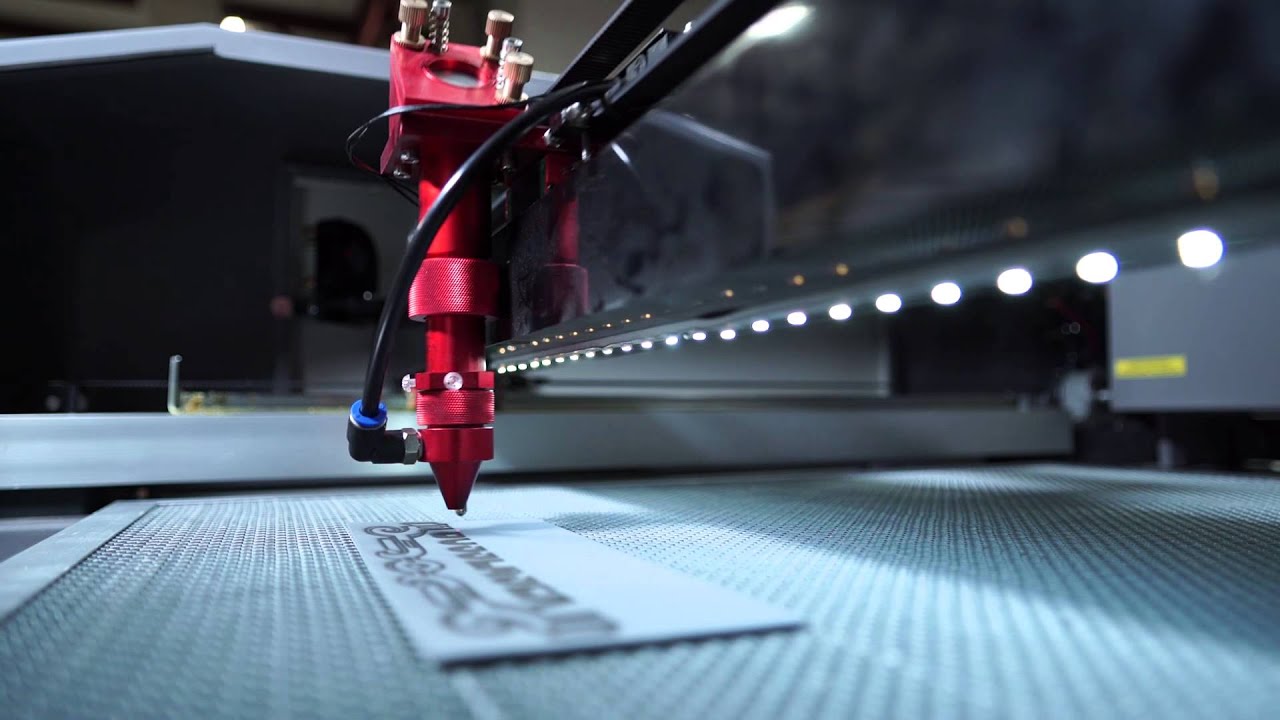

Bosslaser offers hobbyists businesses and educational institutions quality co2 and fiber laser cutter and engraver systems the ability to effectively and accurately design cut and engrave a material to whatever your computer screen can display is an awe inspiring and in demand skill.

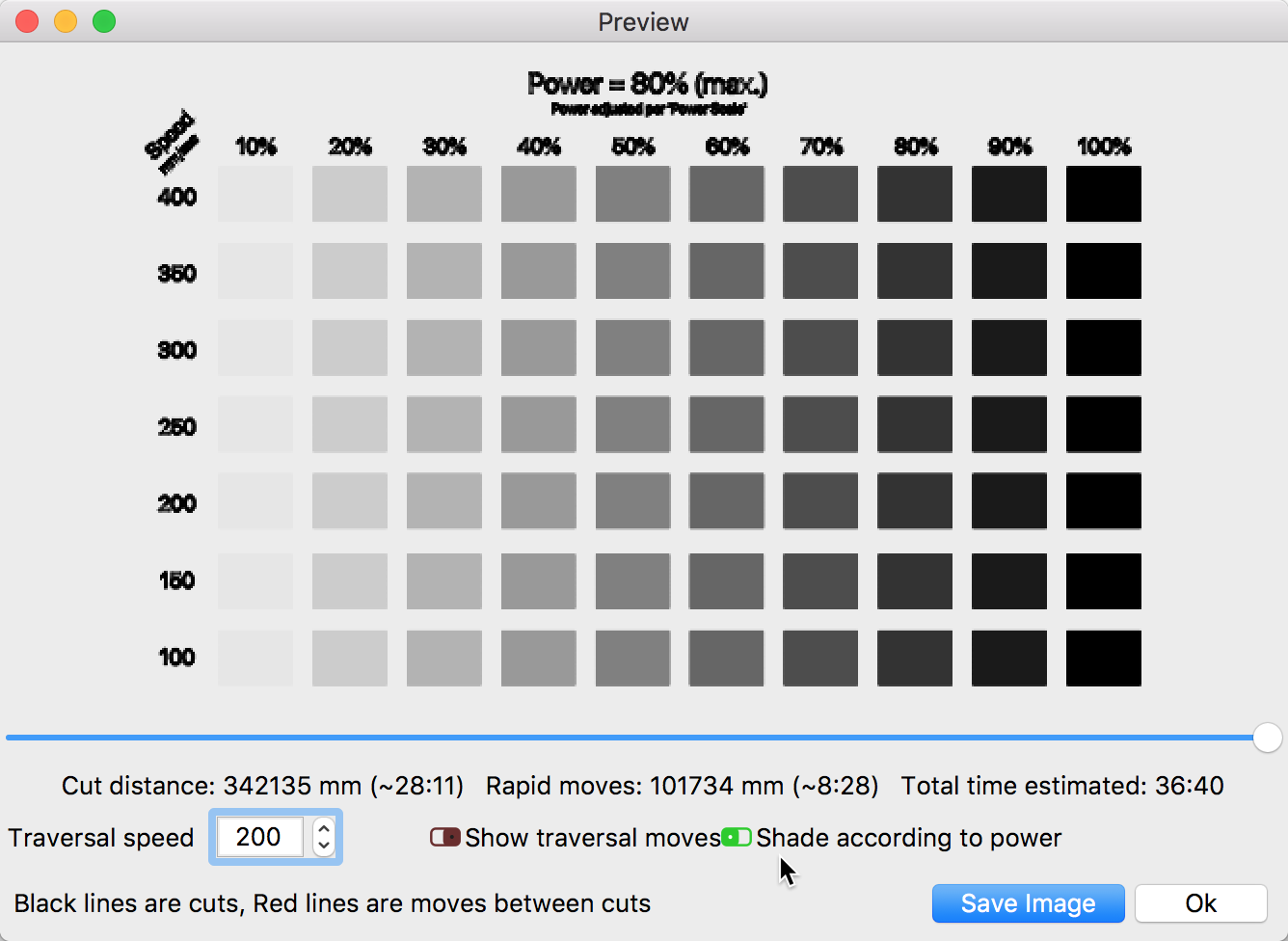

The top right menu bar allows for settings for different materials thicknesses cutting power engraving power layers laser head speeds and scan gaps.

Every type of material will react differently with the laser even from one plastic to the next.

The below is to help you figure out your settings for your cutting job on the boss laser.

Also available is a laser cutter user guide.

Material settings fusion series suggested material settings co2 these are only suggestions.

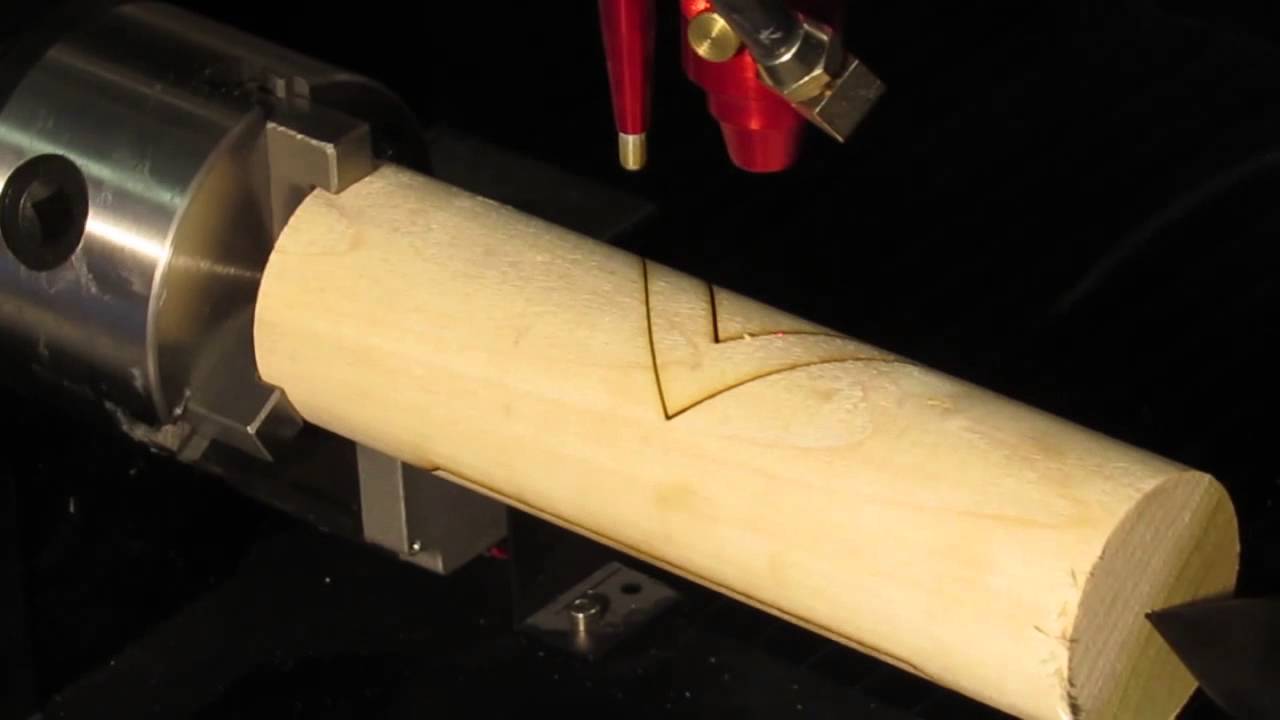

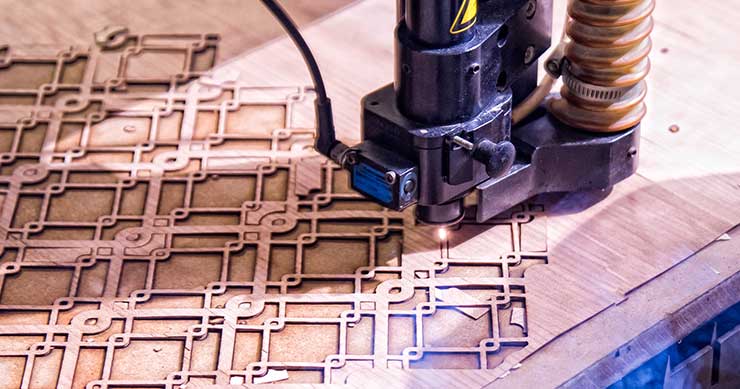

Here you can visually see many of the laser machine applications and materials that we and our clients have processed.

The co2 wavelength makes our industrial co2 laser cutters ideally suited for all types of organic materials such as wood acrylic leather plastics fabrics etc.

Please do not be creative with settings unless you know what you re doing because you can easily set things on fire.

The following are suggested laser cutter configuration settings for various materials.

Boss laser s cutting machines make it easy for anyone to set up and adjust the right print driver settings to control the laser frequency ppi for cutting acrylic.

Laser machines are extremely versatile and can be used for various applications including cutting engraving and marking on materials from wood to glass and steel.

Note that these setting must be tried and fine tuned until ideal settings are.

If you have other settings you d like to suggest please send an email to design help ncsu edu with the details.

The laser has a very tight focus so if lower your material a bit the laser will lose focus and spread out.

Once the acrylic sheet is properly masked and set up on a honeycomb table the result will be a finished acrylic cut leaving edges that appear as if they were flame polished without.

Then i run the laser on a vector setting with a lower power setting and a higher speed.

While other materials can be extremely hazardous to either humans or the machine itself like pvc and abs.